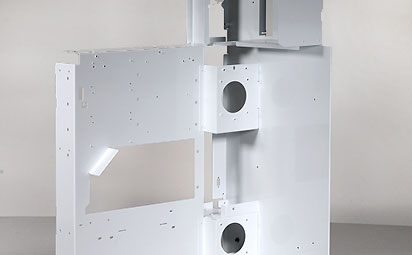

FORM2000 is a fully automated sheet metal manufacturer located in Melbourne specialising in fabricating sheet metal components for OEM manufacturers’ end products.

Our advanced automated sheet metal production facilities provide an integrated end-to-end supply solution while ensuring clients’ sheet metal components are delivered to meet the tightest of manufacturing schedules. We provide a complete end-to-end sheet metal manufacturing service from product design, through prototyping, production to delivery. Our highly experienced production team custom design and manufacture to exacting specifications and to the highest quality and sheet metal finishing standards.

FORM2000 is a sheet metal fabricator located in Melbourne, supplying clients with custom sheet metal products Australia wide.

Contact us today to discuss your sheet metal requirements.

FORM2000 invests in ensuring we offer the latest in sheet metal factory automation technology allowing us to run high mix, and varying volume of OEM sheet metal components to meet the needs of multiple sheet metal OEM clients and/or product variations.

Our Melbourne based factory facilities can easily accommodate small, large, simple or complex custom sheet metal component manufacturing projects depending on the application.

Precision automated sheet metal fabrication machinery and refined production processes allow us to push the boundaries of design innovation and to manufacture sheet metal components not previously available in sheet metal manufacturing.

FORM2000 is more than just a sheet metal factory. Our approach is to work with clients to help them achieve amazing results from sheet metal products with high attention to design, optimising production, utilising advanced sheet metal fabrication techniques and delivering a high quality consistent end product.

FORM2000 works with our customers to develop fit-for-purpose custom sheet metal products. We offer a collaborative design process that starts with concept development. Once your requirements for sheet metal products are understood and agreed, our design team develop 3D concepts, assess buildability and provide cost estimates. Sheet metal product prototypes can be manufactured for assessing fit and built form. Once design approved, our engineers plan the manufacturing process and provide final costings.

Of course, you might know exactly what you want and can provide final specifications. Whatever your sheet metal fabrication need, FORM2000 provides you with the fastest path toward a delivered high quality sheet metal product to suit your supply chain.

When it comes to sheet metal fabrication, manufacturing sheet metal products and understanding sheet metal OEM product requirements and sheet metal supply chain solutions, FORM2000 delivers the best solution.

Automated machinery provides many benefits. FORM2000’s sheet metal fabrication process is suited to high mix, low volume production runs enabling us to break your order down for split deliveries.

Let’s say that over a 12 month period you forecast the need for 1,000 components but don’t want to take delivery of the entire order in one batch. FORM2000 can manufacture that order in a number of short runs over the year to meet your short term sheet metal manufacturing requirements. Less cash tied-up in inventory and less inventory to warehouse.

Importantly, our automated sheet metal fabrication guarantees that each time we set-up to run your component it is manufactured exactly the same as previous batches with no variation.